Mercury Ev-Tech rises after commissioning 3.2 GW battery manufacturing facility in Vadodara

Mercury EV-Tech Commissions 3.2 GW Battery Manufacturing Facility in Vadodara, Eyes Expansion in South India

-

- by Admin,

- April 15, 2025

- on Business-standard

Mercury Ev-Tech gained 3.53% to Rs 59 after the company announced that its subsidiary PowerMetz Energy has commissioned a 3.2 GW lithium-ion battery manufacturing facility at its Vadodara campus.

The shares of Mercury EV Tech surged over 5% in early trade after the company announced that it will commission a 3.2 GW lithium-ion battery manufacturing facility at its Vadodara Campus through its fully owned subsidiary PowerMertz Energy Pvt. Ltd. The EV equipment manufacturing stock opened at Rs 59.00 on BSE, surging Rs 4 or over 3% against previous day's closing price of Rs 56.15 and rose over 5 per cent to hit intraday high at Rs 61.00.

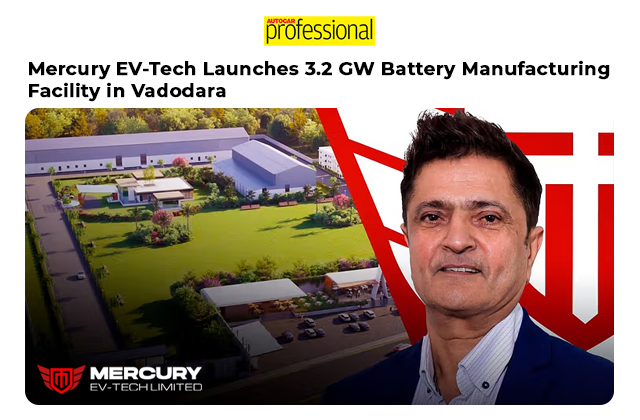

The said facility hosts a next-generation battery architecture hub, housing the infrastructure to develop and produce an extensive range of chemistries including LFP (lithium iron phosphate), NMC (nickel manganese cobalt), sodium-ion cells and supercapacitor modules.

This multi-chemistry facility would enable the company to cater to an increasingly diverse set of high-utility applicationsfrom electric mobility to stationary energy storage.

The equipment is scheduled to reach the Vadodara campus by end-April, with pilot production set to begin mid-May 2025.

Darshal Shah from Mercury EV-Tech said: This upcoming facility is poised to be one of the most advanced lithium-ion battery lines in the country, equipped with cutting-edge automation and a rare integrated laboratory designed to meet stringent global safety and performance standards.

Indias policy landscape has taken a decisive turn with over 30 GW of Battery Energy Storage Systems (BESS), including standalone BESS, auctioned across multiple routes in the past six months. The recent regulatory mandate for a minimum of two hours of BESS integration with all government renewable projects presents a substantial opportunity, driving strong demand for advanced energy storage solutions.

Mercury EV-Tech, through PowerMetz, is positioned to emerge as a key implementing partner and a preferred supplier in this transformative shift.

We have plans to initiate work on an additional 3.2 GW battery plant in South India, with the Vadodara facilitys performance and order pipeline providing the foundation for this expansion.

Preliminary land evaluations have been conducted across four to five locations, and the final site will be selected in line with operational momentum and order book strength over the coming quarters.

Mercury EV Tech, an electric vehicle solutions provider, delivers end-to-end capabilities across the EV manufacturing spectrum.

Disclaimer: No Business Standard Journalist was involved in creation of this content

Robotic Battery Production Line to Boost Mercury EV-Tech's Manufacturing Capabilities

-Business-standard

In alignment with global automation standards, Mercury EV-Tech has placed an order for a fully robotic, high-throughput production line from one of Chinas top-tier equipment providers. A technical team from India is set to inspect the facility in China on 15 April 2025, ahead of machinery shipment.